Modified material PA66-GF, FR for auto radiators

Nylon 66 is frequently used when high mechanical strength, rigidity, good stability under heat and/or chemical resistance is required. It is used in fibers for textiles and carpets and molded parts. For textiles, fibers are sold under various brands, for example Nilit brands or the Corduroy brand for luggage, but it is also used in airbags, apparel, and for carpet fibers under the Ultra brand. Nylon 66 lends itself well to make 3D structural objects, mostly by injection molding. It has broad use in automotive applications; these include "under the hood" parts such as radiator end tanks, rocker covers, air intake manifolds, and oil pans, as well as numerous other structural parts such as hinges, and ball bearing cages. Other applications include electro-insulating elements, pipes, profiles, various machine parts, zip ties, conveyor belts, hoses, polymer-framed weapons, and the outer layer of turnout blankets. Nylon 66 is also a popular guitar nut material.

Nylon 66, especially glass fiber reinforced grades, can be effectively fire retarded with halogen-free products. Phosphorus-based flame retardant systems are used in these fire-safe polymers and are based on aluminum diethyl phosphinate and synergists. They are designed to meet UL 94 flammability tests as well as Glow Wire Ignition Tests (GWIT), Glow Wire Flammability Test (GWFI) and Comparative Tracking Index (CTI). Its main applications are in the electrical and electronics (E&E) industry.

PA66 Features

It has excellent mechanical properties, high strength, high toughness, but high water absorption, so the dimensional stability is poor.

PA66 resin itself has excellent fluidity, no need to add flame retardant to reach V-2 level

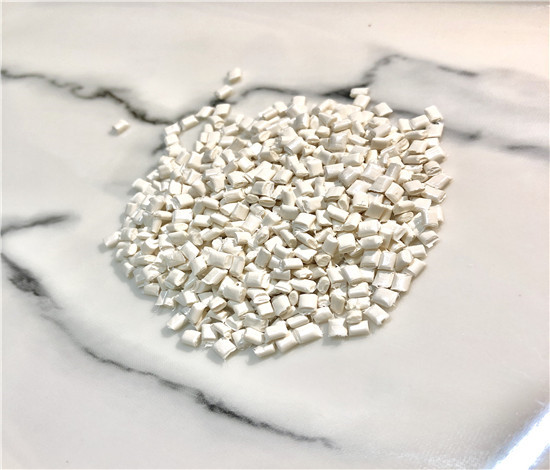

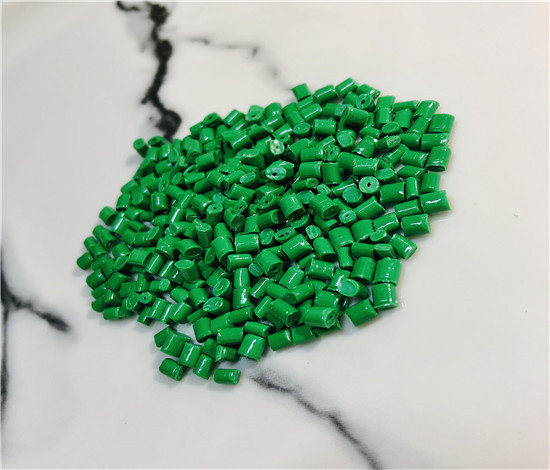

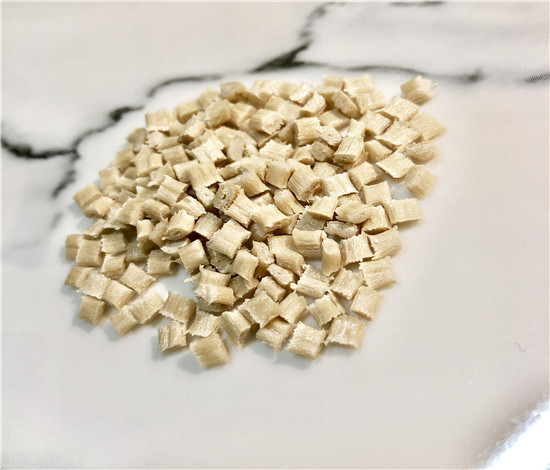

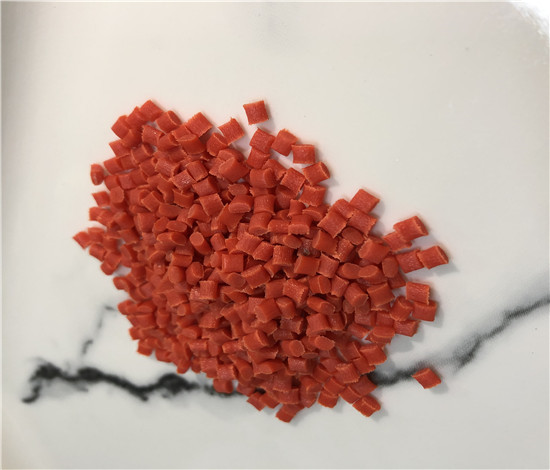

The material has excellent coloring ability, can achieve various requirements of color matching

The shrinkage rate of PA66 is between 1% and 2%. The addition of glass fiber additives can reduce the shrinkage rate to 0.2%~1%. The shrinkage ratio is large in the flow direction and in the direction perpendicular to the flow direction.

PA66 is resistant to many solvents, but is less resistant to acids and other chlorinating agents.

PA66 excellent flame retardant performance, by adding different flame retardants can achieve different levels of flame retardant effect.

PA66 Main Application Field

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure products, oil pipes, fuel tanks and some precision engineering products.

| Field | Description |

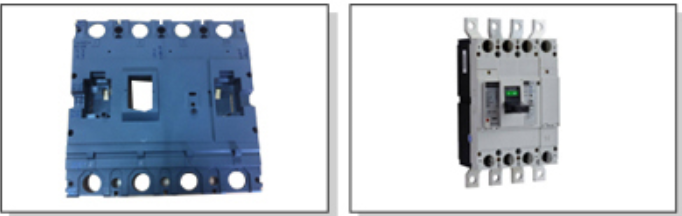

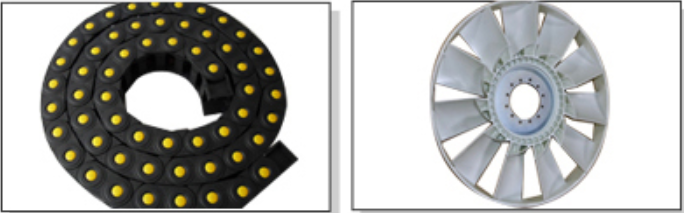

| Auto Parts | Radiators, cooling fan, door handle, fuel tank cap, air intake grille, water tank cover, lamp holder |

| Electrical & Electronic parts | Connector, bobbin, timer, cover circuit breaker, switch housing |

| Industrial parts and consumer products | Industrial parts and consumer products |

SIKO PA66 Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SP90G10-50 | 10%-50% | HB | PA66+10%, 20%, 25%,

30%,50%GF, Glassfiber reinforced grade |

| SP90GM10-50 | 10%-50% | HB | PA66+10%, 20%, 25%,

30%,50%GF, Glassfiber and mineral filler reinforced grade |

| SP90G25/35-HSL | 25%-35% | HB | PA66+25%-35%GF, heat

resistance,hydrolysis and glycol resistance |

| SP90-ST | NONE | HB | PA66, PA66+15%, 20%,

30%GF,Super Toughness grade, High impact, Dimension stability, low temperature resistance. |

| SP90G20/30-ST | 20%-30% | HB | |

| SP90F | NONE | V0 | Unfilled,Flame retardant

PA66 |

| SP90F-GN | NONE | V0 | Unfilled, Halogen free

Flame retardant PA66 |

| SP90G25/35F-RH | 15%-30% | V0 | PA66+ 25%, 30%GF, and

FR V0 grade, Red phosphorus halogen free |

| SP90G15/30F-GN | 15%-30% | V0 | PA66+15%, 20%, 25%,

30%GF, and Halogen free FR V0 grade |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PA66 | PA66+33%GF | SP90G30 | DUPONT 70G33L, BASF A3EG6 |

| PA66+33%GF, Heat stabilized | SP90G30HSL | DUPONT 70G33HSL, BASF A3WG6 | |

| PA66+30%GF, Heat stabilized, hydrolysis | SP90G30HSLR | DUPONT 70G30HSLR | |

| PA66, high impact modified | SP90-ST | DUPONT ST801 | |

| PA66+25%GF, FR V0 | SP90G25F | DUPONT FR50, BASF A3X2G5 | |

| PA66 Unfilled, FR V0 | SP90F | DUPONT FR15, TORAY CM3004V0 |