Introduction

General performance ABS engineering plastics appearance for the opaque in ivory aggregate, manage to make do their products into a colorful, and with a high gloss ABS relative density of 1.05 or so, bibulous rate is the combination of low ABS with other materials and easy to ABS surface printing coating and the coating treatment of oxygen index of 18 ~ 20, belong to flammable polymers, flame yellow, have black smoke, and a special 2 mechanics performance of cinnamon.

ABS with excellent mechanical properties, and its excellent impact strength, can be used under low temperature: ABS good wear resistance and good dimensional stability, but also has oil resistance, can be used for the medium load and rotating speed of the bearing under the ABS creep resistance is greater than the PSF and PC, but smaller than the PA and POM ABS bending strength and compression strength of plastic in poor mechanical properties are greatly influenced by the temperature of ABS 3 heat distortion temperature of the thermal performance of ABS is 93 ~ 118, products after annealing treatment can improve around 10 ABS in – 40 an still show a little toughness, can be used in 40 ~ 100 – temperature range 4 electrical properties of ABS has good electrical insulation, and almost not affected by temperature humidity and frequency, can be used in most circumstances 5 environmental performance of ABS is not affected by inorganic salt alkali and acid water, but soluble in ketone aldehyde and chlorinated hydrocarbon, corroded by ice acetic acid vegetable yield stress cracking ABS weather resistance is poor, under the action of ultraviolet light, easy to produce degradation; After being outdoors for half a year, the impact intensity decreased by half.

Application

The biggest applications of ABS resin are in automotive, electronics, building materials and DIY manufacturing.

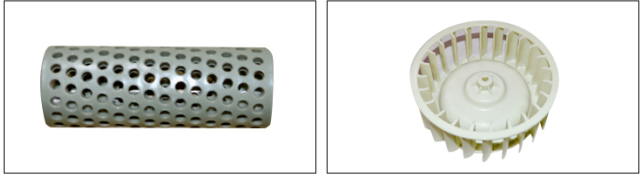

The use of the automotive field includes automobile dashboard, body exterior board, interior decoration board, steering wheel, soundproof board, door lock, bumper, ventilation pipe and many other components.

It is widely used in electric appliances such as refrigerators, televisions, washing machines, air conditioners, computers, copiers, etc. In building materials, ABS sanitary ware and ABS decorative board are widely used in building materials industry. DIY, model wings, etc.

ABS is also widely used in packaging, furniture, sports and entertainment products, machinery and instrumentation industries. The important objectives of automotive interior include beauty, low odor, mechanical properties, heat resistance, weather resistance, etc. Automotive materials can meet the use requirements of various interior parts; the materials have the following conditions:

1. Good mobility

2. Excellent impact resistance

3. Easy to process and form

4. Easy to color and spray

5. Good corrosion resistance

3d Printing field

ABS engineering plastic is one of the main materials for 3D printing, so it can become the consumable material for 3D printing because of its characteristics. ABS plastic has such characteristics as heat resistance, impact resistance, low temperature resistance, chemical resistance, excellent electrical performance and stable size of products.

ABS is very mature products in our company, not only reinforced with glass fiber, but also color matched. Suzhou SIKO new material company has experience to meet every customer requirements. Especially we are one-stop solution can save many customers time.

Post time: 12-11-21