Polybutylene terephthalate(PBT). At present, more than 80% of the world’s PBT are modified after use, PBT modified engineering plastics with its excellent physical, mechanical and electrical characteristics in the electrical and electronic field is increasingly widely used.

Modified PBT material properties

1. Excellent mechanical properties, especially high rigidity and hardness;

2. Good heat resistance, thermal deformation temperature can reach 180℃ or above;

3. Good surface gloss performance, especially suitable for spraying free electronic and electrical products;

4. Fast crystallization speed, good fluidity, good molding;

5. Good thermal stability, especially low thermal expansion rate and size shrinkage rate;

6. Good resistance to chemicals, solvents, weather resistance, high dielectric strength, good electrical performance;

7. Low hygroscopicity, little influence on electrical and dimensional stability.

PBT material series products

|

NO. |

Modification Plan |

Property |

Application |

|

Glassfiber Reinforced |

Modified PBT, with glassfiber reinforced |

+20% GF |

Home appliance skeleton, power tool exterior, lawn mower |

|

|

|

+30% GF |

|

|

|

|

+40% GF |

|

|

Flame Retardant Grade |

Modified PBT, flame retardant |

+15% GF, FR V0 |

Electrical connector, compressor terminal board, electric housing, lamp holder material |

|

|

|

+30% GF, FR V0 |

|

|

|

Modified PBT, halogen-free flame retardant |

Halogen-free flame retardant |

Electrical connector, compressor terminal board, electric housing, lamp holder material |

|

|

|

General FR V0 |

Connectors, timers, electrical switches, adapters |

|

|

Normal flame retardant |

Paper white FR V0 |

|

|

Filled Grade |

Modified PBT, with mineral reinforced |

Filler reinforced, good dimensional stability |

Auto parts |

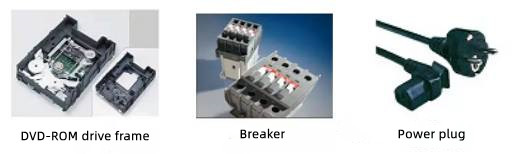

Application of PBT in electronic and electrical industry

|

Electrical name |

Energy-saving lamp |

Television |

Computer |

Vending machines, telephones |

|

PBT’s specific applications |

Energy-saving lamp head |

Partial coil frame |

Slots and connectors on the motherboard |

Part of telephone enclosure |

|

|

|

Focusing potentiometer housing |

External ports such as USB |

Partial coil frame |

|

|

|

Connector on circuit board |

Heat dissipation fan on the CPU chip |

Miniature relay housing |

|

|

|

Miniature relay housing |

Cooling fan |

Connecter |

1. Energy-saving lamp holder

PBT is widely used in the energy saving lamp industry. More than 90% of plastic energy saving lamp heads are made of PBT material. Product performance requirements good color, color transparent, color selection, UL94 flame retardant V0, good electrical insulation, good mechanical properties, easy to process.

2. The connector

Connector material is mainly glass fiber reinforced PBT, performance requirements to UL 94 V0 flame retardant, good strength and toughness, low moisture absorption, electrical and dimensional stability little influence, good surface, good luster, no obvious floating fiber.

3. Computer cooling fan

The product performance requirements can withstand the high temperature of 130℃ for a long time, good surface gloss performance and high flame retardant performance.

4. Other products

Post time: 11-10-22