In recent years, with the increasing demands for environmental improvement and the continuous strengthening of national plastic pollution control, China’s biodegradable materials industry has ushered in a great opportunity for development.

New biodegradable materials, led by biodegradable plastics, which are considered to be the most effective solution to the “white pollution” of disposable plastics, are coming into people’s attention more and more.

Next, I would like to introduce some commonly used biodegradable materials.

PLA

Polylactic acid (Poly lactic acid PLA) is the most widely used degradable material, also known as polylactide, which does not exist in nature and is generally polymerized with lactic acid as the main raw material.

The general principle is that starch raw materials are saccharified to glucose, and then glucose and certain bacteria are fermented to produce high-purity lactic acid, and then polylactic acid with a certain molecular weight is synthesized by chemical synthesis.

PBAT.

PBAT belongs to thermoplastic biodegradable plastics. It is a copolymer of butylene adipate and butylene terephthalate. It has the characteristics of both PBA and PBT. It not only has good ductility and elongation at break, but also has good heat resistance and impact properties. In addition, it also has excellent biodegradability.

Among them, raw materials such as butanediol, oxalic acid and PTA are easily available and can be widely processed in many forms, such as injection molding, extrusion molding, blow molding and so on.

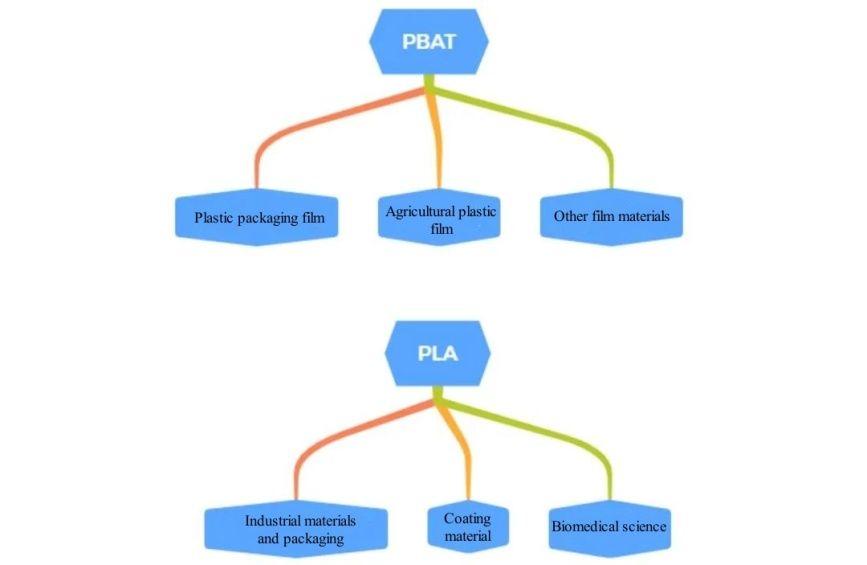

At present, the biodegradable plastic products used on a large scale in the market have been modified or compounded, in which PBAT is mainly used with PLA. For example, the biodegradable plastic bag used on a large scale is the composite material of PLA and PBAT.

Comparison of downstream applications between PBAT and PLA

PBS.

PBS is called polybutylene succinate. In the 1990s, Showa Polymer Company of Japan first used isocyanate as chain extender and reacted with low molecular weight polyester synthesized by Polycondensation of dicarboxylic glycol to prepare high molecular weight polymers. PBS polyester began to attract wide attention as a new type of biodegradable plastics. Compared with other traditional biodegradable polyesters, PBS has the advantages of low production cost, relatively high melting point, good heat resistance and mechanical properties. its raw material source can be obtained not only from petroleum resources, but also from biological resources fermentation. under the condition that oil and other non-renewable resources are increasingly exhausted, this characteristic has far-reaching significance.

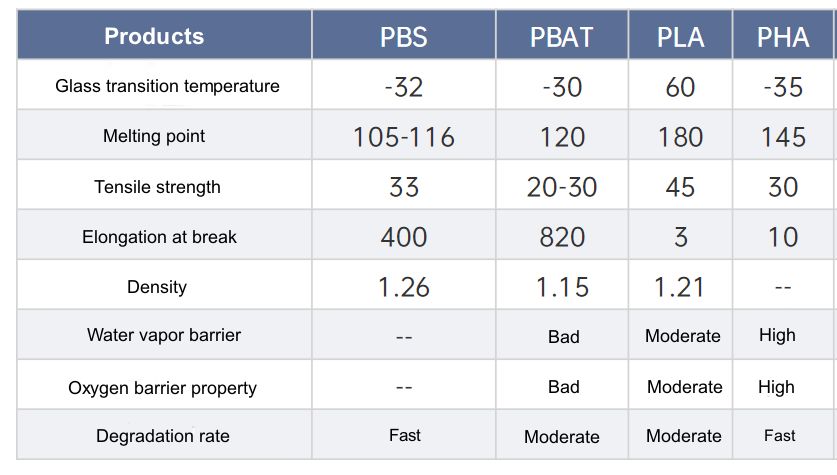

Summary, comparison of material properties between PBS,PLS,PBAT and PHA

At present, the material properties of commonly used biodegradable plastics are different. PLA has good transparency, glossiness, high melting point and strength, but low tensile toughness and crystallinity. PBAT has the characteristics of both PBA and PBT, and has good ductility and elongation at break. But its water vapor barrier and oxygen barrier are poor. PBS has good water resistance, heat resistance and comprehensive properties, wide processing temperature window, and has the best processing performance in universal degradable plastics. The hot deformation temperature of PBS is close to 100C, and it can be higher than 100C after modification. However, PBS also has some shortcomings such as low melt strength and slow crystallization rate. In terms of biodegradability, PLA degradation conditions are more stringent, PBS and PBAT are easier to be degraded. It should be noted that the biodegradation of PLA, PBS and PBAT can not occur under any conditions, and is usually degraded by enzymes and microorganisms in the environment of compost, soil, water and activated sludge.

To sum up, the performance of a single degradable plastic raw material has its own defects, but after copolymerization, blending, auxiliaries and other modifications, it can basically cover the application of disposable plastics such as PE, PP in packaging, textile, disposable tableware and so on.

Post time: 20-12-22