PEEK is a high-performance organic thermoplastic polymer with excellent mechanical properties, high temperature properties, mechanical strength and excellent chemical resistance. It is an all-round special engineering plastic suitable for various additive manufacturing technologies. In recent years, its demand has grown rapidly, and it is widely used in many application fields and plays an important role.

1.Aerospace

Aerospace is the first application field developed by PEEK. PEEK has many performance advantages in this field, such as high temperature resistance, excellent machining, radiation resistance, low smoke, flame retardant, non-toxic, corrosion resistance, hydrolysis resistance and so on. Therefore, PEEK can replace aluminum and other metal materials to manufacture various aircraft parts, which can reduce the weight by up to 70% compared with metal and improve fuel efficiency.

The excellent characteristics of PEEK can be used to manufacture fuel filters, bolts, nuts and spools, cabin seats and dining tables, cabin skins, cable trays and electrical components, radomes, landing gear hubcaps, manhole covers, Fairing bracket, compressor and pump body and so on.

2.Automotive industry

PEEK has good friction resistance, mechanical properties and easy processing properties for automotive using, which not only greatly reduces the processing cost and weight, but also ensures a long service life. PEEK can replace metal as automobile seal ring, bearing fittings, engine fittings, bearing sleeve, air intake grille. It can also be used to achieve lightweight.

3.Electrical and electronic field

In terms of electronic appliances, PEEK resin has excellent electrical properties and is a good electrical insulator. It can still maintain good electrical insulation in harsh working environments such as high temperature, high pressure and high humidity. Widely used in mobile phone gasket, dielectric film, High temperature electronic element, high-temperature connector

4.Medical industry

PEEK has the advantages of non-toxicity, excellent biocompatibility, light weight and corrosion resistance. It is a potential bioprosthesis material.

In addition to the use of PEEK for surgeries, dental equipment and some tight medical equipment that require high sterilization and need to be used multiple times, the most important use is to replace the artificial bone built by metal, and organically combined with the body, it is the closest to human bone. s material.

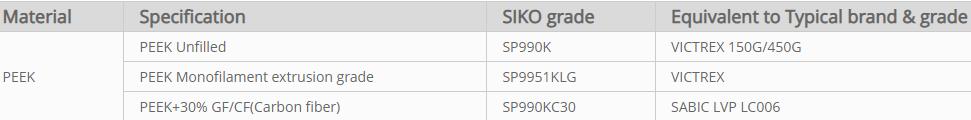

SIKOPOLYMERS’ Main grades of PPS and their equivalent brand and grade, as following:

Post time: 08-08-22