News

-

Introduction to the Color Masterbatch Used to Match Plastic Granules

What is color masterbatch? Color masterbatch, is a new type of polymer material special colorant, also known as pigment preparation. It is composed of three basic elements: pigment or dye, carrier and additive. It is the aggregate of super constant pigment or dye uniformly attached to resin. ...Read more -

Summary of ABS and PMMA Performance, Processing Characteristics and Typical Applications

ABS Performance of ABS ABS is composed of three chemical monomers acrylonitrile, butadiene and styrene. From the perspective of morphology, ABS is a non-crystalline material, with high mechanical strength and a good “strong, tough, steel” comprehensive performance. It is an amorphou...Read more -

Summary of PPO, PC and PBT Performance, Processing Characteristics and Typical Applications

PPO Performance of PPO Polyphenylether is poly2, 6-dimethyl-1, 4-phenylether, also known as polyphenyloxy, Polyphenyleneoxiole (PPO), modified polyphenylether is modified by polystyrene or other polymers (MPPO). PPO is a kind of engineering plastic with excellent comprehensive performance, highe...Read more -

Causes and Solutions of Surface Cracks in Plastic Parts

1. Residual stress is too high In the process operation, it is the easiest way to reduce the residual stress by reducing the injection pressure, because the injection pressure is proportional to the residual stress. If the cracks on the surface of the plastic parts are black around, it indicates...Read more -

How to Improve The Quality of Nylon Injection Molded Parts

Ensure drying Nylon is more hygroscopic, if exposed to the air for a long time, will absorb moisture in the atmosphere. At temperatures above the melting point (about 254 ° C), water molecules react chemically with nylon. This chemical reaction, called hydrolysis or cleavage, oxidizes the nylon a...Read more -

Causes And Solutions of Dents And Pores in Injection Molding Products

In the process of product production, product dents and pores are the most frequent adverse phenomena. The plastic injected into the mold shrinks in volume as it cools. The surface hardens first when it cools earlier, and bubbles form inside. The indentation is the slow cooling part of the bubble...Read more -

Classification of High Temperature Nylon PA and Its Application in Electronic Field

High temperature nylon (HTPA) is a special nylon engineering plastic that can be used in the environment of 150℃ or more for a long time. The melting point is generally 290℃~320℃, and the thermal deformation temperature can reach 290℃ after modification of glass fiber, and maintains excellent mec...Read more -

Polyphenylene Sulfide (PPS) – New 5G Opportunity

Polyphenylene sulfide (PPS) is a kind of thermoplastic special engineering plastic with good comprehensive properties. Its outstanding characteristics are high temperature resistance, corrosion resistance and superior mechanical properties. PPS is widely used in automo...Read more -

Property and Application of Flame Retardant PC Materials and Alloys

Polycarbonate (PC), is a colorless transparent thermoplastic material. The flame retardant principle of flame retardant PC is to catalyze the combustion of PC into carbon, so as to achieve the purpose of flame retardant. Flame retardant PC materials are widely used in electronic and electrical fi...Read more -

Application of Engineering Plastic PBT in Electronic and Electrical Industry

Polybutylene terephthalate(PBT). At present, more than 80% of the world’s PBT are modified after use, PBT modified engineering plastics with its excellent physical, mechanical and electrical characteristics in the electrical and electronic field is increasingly widely used. Modified PBT mat...Read more -

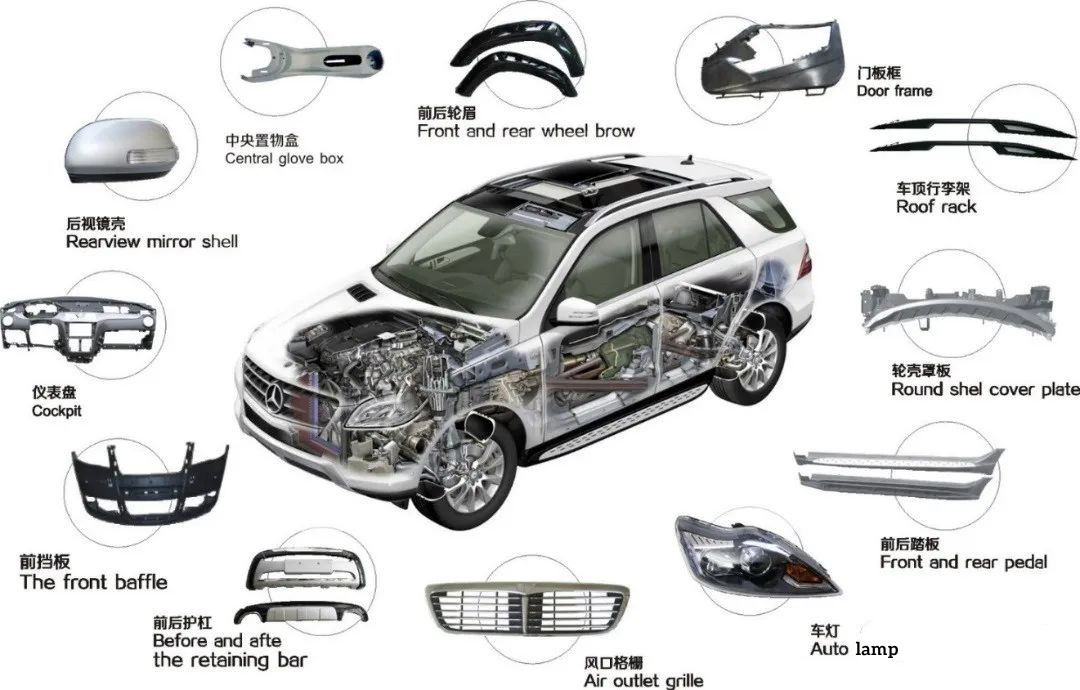

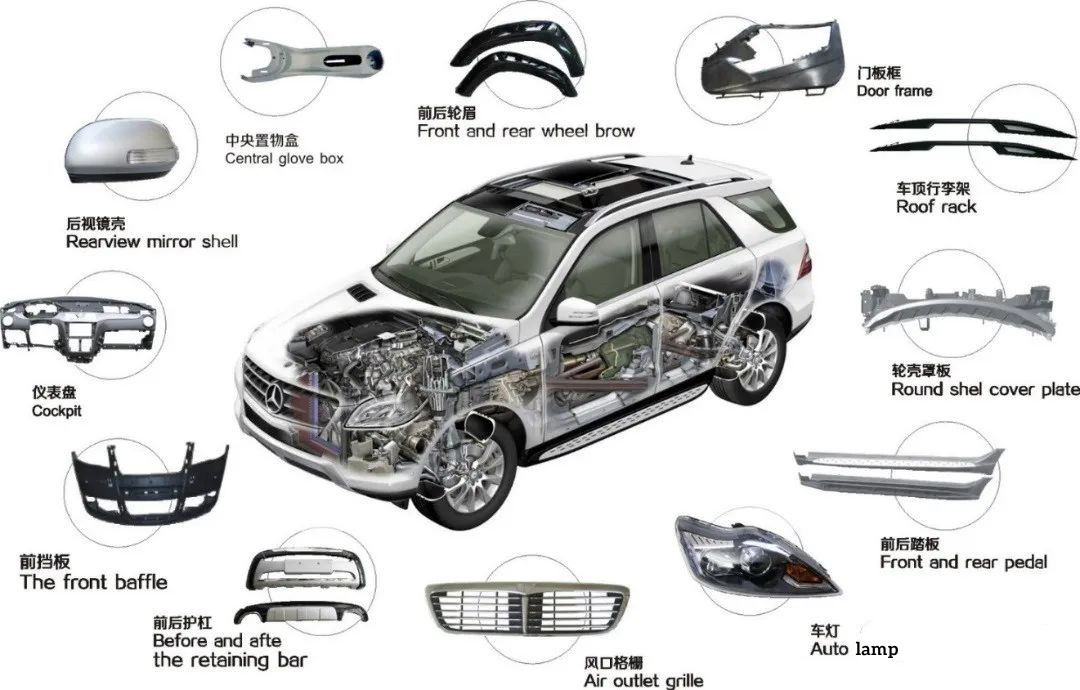

Engineering Plastics Used in The New Energy Vehicle Industry

The use of engineering plastics for new energy vehicles combined with automotive products needs to meet the following performance requirements: 1. Chemical corrosion resistance, oil resistance, high and low temperature resistance; 2. Excellent mechanical properties, high fluidity, excellent proce...Read more -

Properties and Applications of SIKO’s PBT Materials

PBT engineering plastics, (polybutylene terephthalate), has excellent comprehensive performance, relatively low price, and has good molding processing. In electronics, electrical appliances, mechanical equipment, automotive and precision instruments and other fields, it has been widely used. Char...Read more