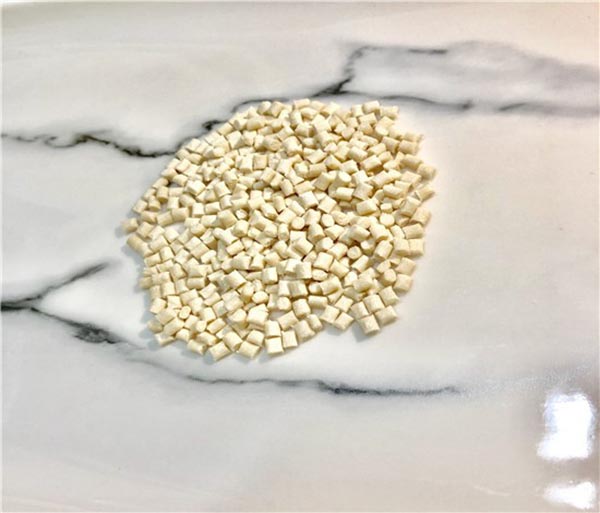

PPO

Performance of PPO

Polyphenylether is poly2, 6-dimethyl-1, 4-phenylether, also known as polyphenyloxy, Polyphenyleneoxiole (PPO), modified polyphenylether is modified by polystyrene or other polymers (MPPO).

PPO is a kind of engineering plastic with excellent comprehensive performance, higher hardness than PA, POM, PC, high mechanical strength, good rigidity, good heat resistance (thermal deformation temperature of 126℃), high dimensional stability (shrinkage rate of 0.6%), low water absorption rate (less than 0.1%). The disadvantage is that the UV is unstable, the price is high and the amount is small. PPO is non-toxic, transparent, relatively small density, with excellent mechanical strength, stress relaxation resistance, creep resistance, heat resistance, water resistance, water vapor resistance.

In a wide range of temperature, frequency variation range of good electrical performance, no hydrolysis, forming shrinkage rate is small, flammable with self-flameout, resistance to inorganic acid, alkali, aromatic hydrocarbon resistance, halogenated hydrocarbon, oil and other poor performance, easy swelling or stress cracking, the main drawback is poor melting liquidity, processing and forming difficulties, most of the practical application for MPPO (PPO blend or alloy).

Process characteristics of PPO

PPO has high melt viscosity, poor liquidity and high processing conditions. Before processing, it is necessary to dry for 1-2 hours at the temperature of 100-120℃, forming temperature is 270-320℃, mold temperature control is appropriate at 75-95℃, and forming processing under the condition of “high temperature, high pressure and high speed”. In the production process of this plastic beer, jet flow pattern (snake pattern) is easy to be produced in front of the nozzle, and the nozzle flow channel is better.

The minimum thickness ranges from 0.060 to 0.125 inches for standard molded parts and 0.125 to 0.250 inches for structural foam parts. The flammability ranges from UL94 HB to V-O.

Typical application range

PPO and MPPO are mainly used in electronic appliances, automobiles, household appliances, office equipment and industrial machinery, etc., using MPPO heat resistance, impact resistance, dimensional stability, abrasion resistance, flaking resistance;

PC

Performance of PC

PC is a kind of formless, odorless, non-toxic, highly transparent colorless or slightly yellow thermoplastic engineering plastics, with excellent physical and mechanical properties, especially excellent impact resistance, high tensile strength, bending strength, compression strength; Good toughness, good heat and weather resistance, easy coloring, low water absorption.

The thermal deformation temperature of PC is 135-143℃, the creep is small and the size is stable. It has good heat and low temperature resistance, stable mechanical properties, dimensional stability, electrical properties and flame retardant in a wide temperature range. It can be used for a long time at -60~120℃.

Stable to light, but not resistant to UV light, good weather resistance; Oil resistance, acid resistance, alkali resistance, oxidation acid and amine, ketone, soluble in chlorinated hydrocarbons and aromatic solvents, inhibit bacterial characteristics, flame retardant characteristics and pollution resistance, long-term in water easy to cause hydrolysis and cracking, the disadvantage is due to poor fatigue strength, easy to produce stress cracking, poor solvent resistance, poor fluidity, poor wear resistance. PC injection molding, extrusion, molding, blow molding, printing, bonding, coating and machining, the most important processing method is injection molding.

Process characteristics of PC

PC material is more sensitive to temperature, its melting viscosity with the increase of temperature and significantly reduced, faster flow, not sensitive to pressure, in order to improve its liquidity, to take the method of heating. PC material before processing to fully dry (120℃, 3~4 hours), moisture should be controlled within 0.02%, trace water processing at high temperature will make products produce turbidious color, silver and bubbles, PC at room temperature has a considerable capacity to force high elastic deformation. High impact toughness, so it can be cold pressing, cold drawing, cold roll pressing and other cold forming process. PC material should be molded under the conditions of high material temperature, high mold temperature and high pressure and low speed. For smaller sprue, low speed injection should be used. For other types of sprue, high speed injection should be used.

Mold temperature control in 80-110℃ is better, forming temperature in 280-320℃ is appropriate.

Typical application range

PC’s three application areas are glass assembly industry, automobile industry and electronics, electrical industry, followed by industrial machinery parts, optical disc, civilian clothing, computer and other office equipment, medical and health care, film, leisure and protective equipment

PBT

Performance of PBT

PBT is one of the toughest engineering thermoplastic materials, it is a semi-crystalline material, has very good chemical stability, mechanical strength, electrical insulation characteristics and thermal stability. These materials have good stability in a wide range of environmental conditions, and the PBT moisture absorption characteristics are very weak.

Melting point (225%℃) and high temperature deformation temperature are lower than PET material. Veka softening temperature is about 170℃. The glass transition temperature is between 22℃ and 43℃.

Due to the high crystallization rate of PBT, its viscosity is very low, and the cycle time of plastic parts processing is generally low.

Process characteristics of PBT

Drying: This material hydrolyzes easily at high temperatures, so it is important to dry it before processing. The recommended drying condition in the air is 120C, 6-8 hours, or 150℃, 2-4 hours. The humidity must be less than 0.03%. If using a hygroscopic dryer, the recommended drying condition is 150 ° C for 2.5 hours. The processing temperature is 225~275℃, and the recommended temperature is 250℃. For the unenhanced material mold temperature is 40~60℃.

The cooling cavity of the mold should be well designed to reduce the bending of the plastic parts. Heat must be lost quickly and evenly. It is recommended that the diameter of the mold cooling cavity is 12mm. The injection pressure is moderate (up to 1500bar maximum), and the injection rate should be as fast as possible (because PBT solidifies quickly).

Runner and gate: Circular runner is recommended to increase pressure transfer.

Typical application range

Household appliances (food processing blades, vacuum cleaner components, electric fans, hair dryer housing, coffee utensils, etc.), electrical components (switches, electric housing, fuse boxes, computer keyboard keys, etc.), automotive industry (radiator grates, body panels, wheel covers, door and window components, etc.

Post time: 18-11-22