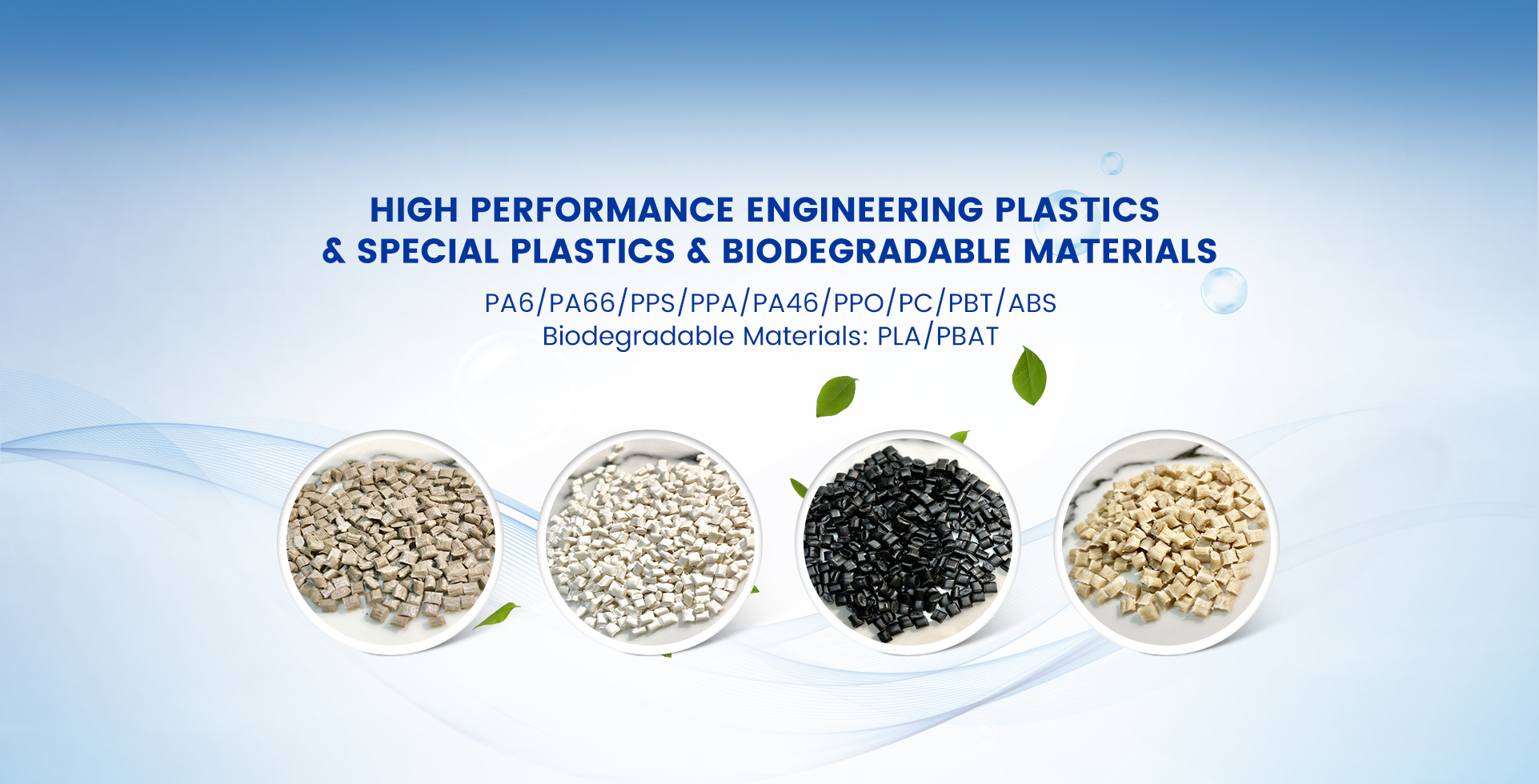

Professional and quickest technical and commercial communication service, from material idea to end product 15 years rich experiences working with worldwide customers, global exporting and domestic foreign investment.

major

products

PA66-GF, FR

PA66-GF, FR

PPS-GF,FR

PPS-GF,FR

Material plastic Polyphenylene sulfide (PPS) is a new type of high performance thermoplastic polymer with excellent high temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced mechanical properties, excellent dimensional stability and excellent electrical properties.

PPA-GF,FR

PPA-GF,FR

Material plastic PPA is stronger and harder than polyamides such as nylon6, and 66, etc.Lower sensitivity to water;Better thermal performance;And creep, fatigue and chemical resistance are much better.

Biodegradable Materials

Biodegradable Materials

about

SIKO

As a professional solution supplier of various engineering plastics and special high performance polymers since 2008, we have been keeping contribute to R&D, produce and supply the most suitable material for our global customers utilization. Helping our customers minimize costs while meeting the strict demanding requirements of a wide range of products, enhancing the competitiveness of products in the market, to achieve good mutual benefit and sustainable development together.

-

Costing Down Safely

Costing Down Safely

In the current competitive market situation, how to costing down safely is always be the first concern of the boss of each company or your customers, we very deeply understand the...

View Details -

New Product Develop & Design

New Product Develop & Design

In order to serve customers and market well, every producer need to be ready for develop and design new products, we will build a quick personal direct discussion bridge...

View Details -

Customized Composite Material

Customized Composite Material

We can customized all properties according to customers request, such as high strength, high impact, enhanced thermal heat stabilized, hydrolysis resistant, UV-resistant,...

View Details -

Technical Service & Supporting

Technical Service & Supporting

We can offer the quickest technical consulting service and support from the project beginning, including prototyping analysis, product structure design suggestion, mold..

View Details

news and information

Matters Needing Attention of PPSU in the Process of Injection Molding

PPSU, the scientific name of polyphenylene sulfone resin, is an amorphous thermoplastic with high transparency and hydrolytic stability, and the products can withstand repeated steam disinfection. PPSU is more common than polysulfone (PSU), polyethersulfone (PES) and polyetherimide (PEI). The app...

Performance Similarity and Comparison Between PEI and PEEK

Polyetherimide, referred to as PEI in English, Polyetherimide, with amber appearance, is a kind of amorphous thermoplastic special engineering plastic which introduces flexible ether bond (- Rmae Omi R -) into rigid polyimide long chain molecules. The structure of PEI As a kind of thermoplastic...

Understanding the Performance and Application of PEEK

Polyether ether ketone resin (polyetheretherketone, referred to as PEEK resin) is a kind of high temperature thermoplastic with high glass transition temperature (143C) and melting point (334C). The load thermal deformation temperature is as high as 316C (30% glass fiber...