High definition Raw Material For Biodegradable Bags - Biodegradable Film Modified Material-SPLA – Siko

High definition Raw Material For Biodegradable Bags - Biodegradable Film Modified Material-SPLA – Siko Detail:

The use of polylactic acid now extends beyond medicine to common items such as packaging bags, crop films, textile fibers and cups. Packaging materials made from polylactic acid were initially expensive, but have now become one of the most common packaging materials. Poly (lactic acid) can be made into fibers and films by extrusion, injection molding and stretching. The water and air permeability of polylactic acid film is lower than that of polystyrene film. Since water and gas molecules are diffused through the amorphous region of the polymer, the water and air permeability of polylactic acid film can be adjusted by adjusting the crystalline of polylactic acid.

Several technologies such as annealing, adding nucleating agents, forming composites with fibers or nano-particles, chain extending and introducing crosslink structures have been used to enhance the mechanical properties of PLA polymers. Polylactic acid can be processed like most thermoplastics into fiber (for example, using conventional melt spinning processes) and film. PLA has similar mechanical properties to PETE polymer, but has a significantly lower maximum continuous use temperature. With high surface energy, PLA has easy printability which makes it widely used in 3-D printing. The tensile strength for 3-D printed PLA was previously determined.

SPLA Features

The definition of biodegradable plastics, it is to point to in nature, such as soil, sand, water environment, water environment, certain conditions such as composting and anaerobic digestion conditions, the degradation caused by microbial action of the existence of nature, andeventually decomposed into carbon dioxide (CO2) and/or methane (CH4), water (H2O) and mineralization of the containing element inorganic salt, and the new biomass (such as the body of microorganisms, etc.) of plastic.

SPLA Main Application Field

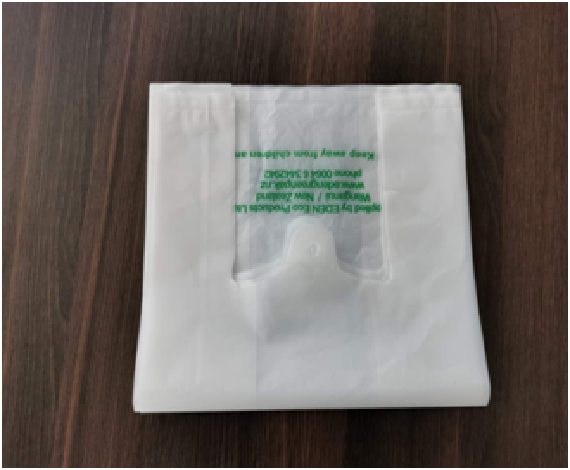

It can completely replace traditional plastic packaging bags, such as shopping bags, handbags, express bags, garbage bags, drawstring bags, etc.

SPLA Grades And Description

| Grade | Description | Processing Instructions |

| SPLA-F111 | The main components of SPLA-F111 products are PLA and PBAT, and their products can be 100% biodegraded after use and waste, and ultimately generate carbon dioxide and water, without polluting the environment. | When using SPLA-F111 blown film on the blown film production line, the recommended blowing film processing temperature is 140-160℃. |

| SPLA-F112 | The main components of SPLA-F112 products are PLA, PBAT and starch, and its products can be 100% biodegraded after use and discard, and ultimately generate carbon dioxide and water without polluting the environment. | When using SPLA-F112 blown film in blown film production line, the recommended blowing film processing temperature is 140-160℃. |

| SPLA-F113 | The main components of SPLA-F113 products are PLA, PBAT and inorganic substances. The products can be 100% biodegraded after use and discarded, and eventually generate carbon dioxide and water without polluting the environment. | When using SPLA-F113 blown film in blown film production line, the recommended blowing film processing temperature is 140-165℃. |

| SPLA-F114 | The SPLA-F114 product is a starch-filled polyethylene modified masterbatch. It uses 50% vegetable-derived starch instead of polyethylene from petrochemical resources. | The product is blended with polyethylene on the blown film production line. The recommended addition amount is 20-60wt%, and the blown film processing temperature is 135-160℃. |

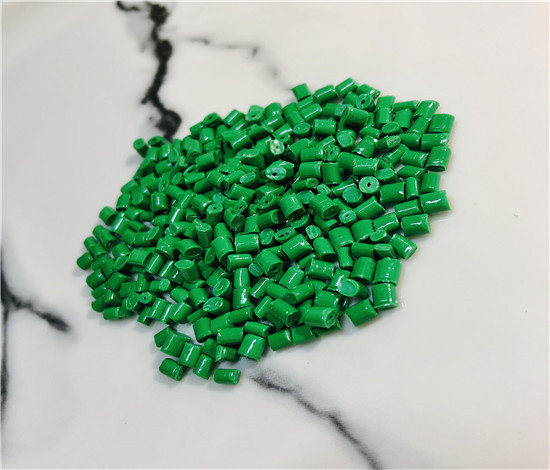

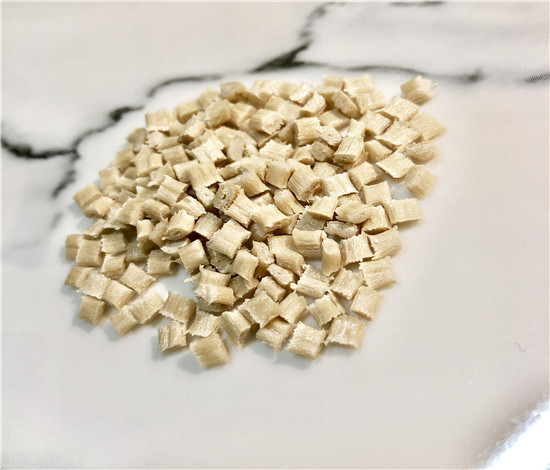

Product detail pictures:

Related Product Guide:

We consistently carry out our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for High definition Raw Material For Biodegradable Bags - Biodegradable Film Modified Material-SPLA – Siko , The product will supply to all over the world, such as: Malta, Guatemala, Marseille, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.