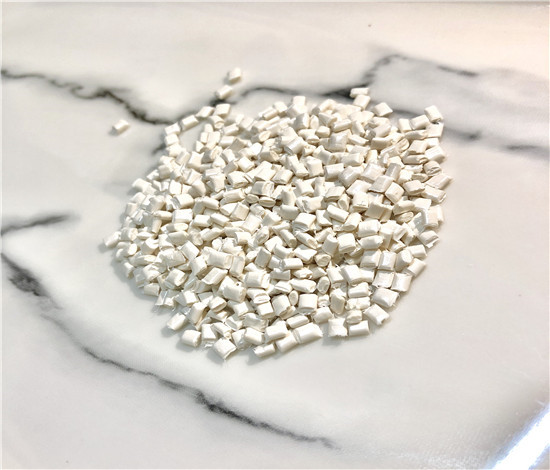

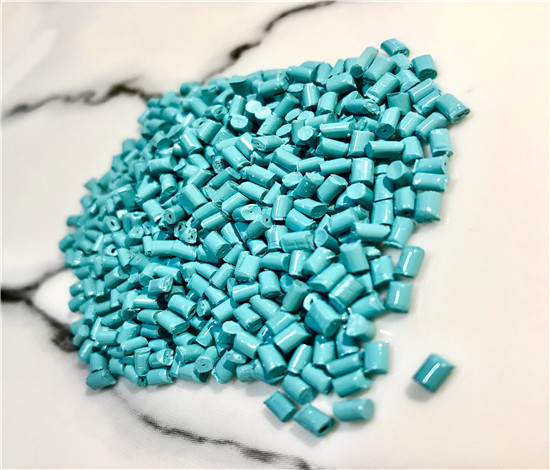

Material plastic PPS+PA66/GF for automotive industry

PPS+PA66/GF Features

It has excellent mechanical properties, high strength, high toughness, but high water absorption, so the dimensional stability is poor.

The density is only 1.5 ~ 1.9g/ cc, but aluminum alloy is around 2.7 g/cc, steel is around 7.8g/cc. It can greatly reduce weight, excellent performance on metal replacement.

By filling the solid lubrication material, making the PPS composite material with good resistance to bite, low friction coefficient, wear resistance, self-lubrication, silencing shock absorption.

The molding shrinkage rate is very small; Low water absorption rate, small linear thermal expansion coefficient; Good dimensional stability will still show under high temperature or high humidity, and the molding shrinkage rate is 0.2 ~ 0.5%.

PPS+PA66/GF Main Application Field

| Field | Application Cases |

| Automotive | Cross connector, brake piston, brake sensor, lamp bracket, etc |

| Household Appliances | Hairpin and its heat insulation piece, electric razor blade head, air blower nozzle, meat grinder cutter head, CD player laser head structural parts |

| Machinery | Water pump, oil pump accessories, impeller, bearing, gear, etc |

| Electronics | Connectors, electrical accessories, relays, copier gears, card slots, etc |

SIKO PPS+PA66/GF Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SPS98G30F/G40F | 30%,40% | V0 | PPS/PA alloy, with 30%/40% GF reinforced |