Mold temperature refers to the surface temperature of the mold cavity that comes into contact with the product in the injection molding process. Because it directly affects the cooling rate of the product in the mold cavity, which has a great impact on the internal performance and appearance quality of the product.

1. Effect of mold temperature on the appearance of products.

Higher temperature can improve the fluidity of the resin, which usually makes the surface of the product smooth and shiny, especially to improve the surface beauty of glass fiber reinforced resin products. At the same time, it also improves the strength and appearance of the fusion line.

As for the etched surface, if the mold temperature is low, it is difficult for the melt to fill the root of the texture, which makes the product surface appear shiny, and the “transfer” can not reach the real texture of the mold surface. The ideal etching effect can be obtained by increasing the mold temperature and material temperature.

2. Influence on the internal stress of the product.

The formation of the forming internal stress is basically caused by the different thermal shrinkage during cooling. When the product is formed, its cooling extends gradually from the surface to the interior, and the surface first shrinks and hardens, and then gradually to the interior. In this process, internal stress is produced due to the difference in shrinkage speed.

When the residual internal stress in the plastic part is higher than the elastic limit of the resin, or under the erosion of a certain chemical environment, cracks will occur on the surface of the plastic part. The study of PC and PMMA transparent resin shows that the residual internal stress in the surface layer is compressed and the inner layer is extensional.

The surface compressive stress depends on its surface cooling condition, and the cold mold makes the molten resin cool down rapidly, which makes the molded products produce higher residual internal stress.

The mold temperature is the most basic condition to control the internal stress. If the mold temperature is changed slightly, the residual internal stress will be greatly changed. Generally speaking, the acceptable internal stress of each product and resin has its lowest mold temperature limit. When forming thin-walled or long flow distance, the mold temperature should be higher than the minimum of general molding.

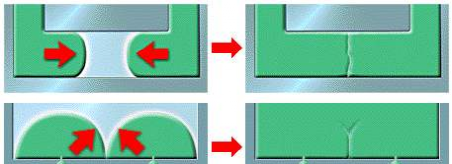

3. Improve product warping.

If the design of the cooling system of the mold is unreasonable or the mold temperature is not controlled properly, and the plastic parts are not cooled enough, it will cause the plastic parts to warp.

For the temperature control of the mold, the temperature difference between the positive mold and the negative mold, the mold core and the mold wall, the mold wall and the insert should be determined according to the structural characteristics of the products, so as to control the cooling shrinkage rate of each part of the molding. after demoulding, the plastic parts tend to bend to the traction direction with higher temperature, so as to offset the orientation shrinkage difference and avoid the plastic parts warping according to the orientation law. For the plastic parts with completely symmetrical shape and structure, the mold temperature should be kept consistent accordingly, so that the cooling of each part of the plastic part should be balanced.

4. Affect the molding shrinkage of the product.

The low mold temperature accelerates the molecular “freezing orientation” and increases the thickness of the frozen layer of the melt in the mold cavity, while the low mold temperature hinders the growth of crystallization, thus reducing the molding shrinkage of the products. On the contrary, when the mold temperature is high, the melt cools slowly, the relaxation time is long, the orientation level is low, and it is beneficial to crystallization, and the actual shrinkage of the product is larger.

5. Affect the hot deformation temperature of the product.

Especially for crystalline plastics, if the product is molded at a lower mold temperature, the molecular orientation and crystallization are instantly frozen, and the molecular chain will be partially rearranged and crystallized in a higher temperature environment or secondary processing conditions, which makes the product deform at or even much lower than the thermal deformation temperature (HDT) of the material.

The correct way is to use the recommended mold temperature close to its crystallization temperature to make the product fully crystallized in the injection molding stage and avoid post-crystallization and post-shrinkage in the high temperature environment.

In a word, mold temperature is one of the most basic control parameters in injection molding process, and it is also the primary consideration in mold design.

Its influence on the forming, secondary processing and final use of products can not be underestimated.

Post time: 23-12-22