Compared with traditional cars, new energy vehicles, on the one hand, have a stronger demand for lightweight, on the other hand, there are more parts related to electricity, such as connectors, charging devices and power batteries, so they have higher requirements for high temperature and high pressure resistance in the selection of materials.

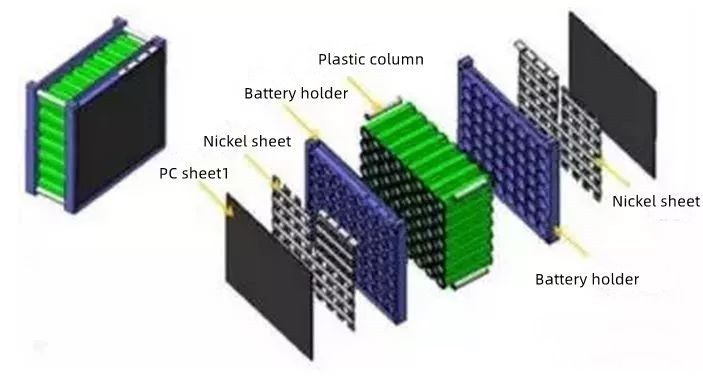

Take the power battery as an example, the power battery in the case of a certain battery energy density, the number of cells is certain, so the weight of the battery is generally from two aspects: one is the structure, the second is the box body.

Structure: bracket, frame, end plate, optional materials are flame retardant PPO, PC/ABS alloy and flame retardant enhanced PA. PPE density 1.10, PC/ABS density 1.2, enhanced flame retardant PA1.58g/cm³, from the point of view of weight reduction, flame retardant PPO is the main choice. And the chemical resistance of PC is relatively poor, and there is electrolyte in lithium battery, so PC is prone to cracking, so many enterprises choose PPO.

Polyphenylene ether is a high-strength engineering plastic developed in the 1960s. Its chemical name is poly2, 6-dimethyl-1, 4-phenyl ether, referred to as PPO (Polyphenylene Oxide) or PPE (Polypheylene ether), also known as Polyphenylene Oxide or Polyphenylene ether.

The modified PPO material has good chemical resistance and good corrosion resistance to lithium cobalt acid, lithium manganate and other materials. The advantages of modified PPO material polyphenyl ether are good size stability, excellent flame retardancy, low temperature resistance and impact resistance. It is one of the ideal materials for the protective shell of lithium battery.

1. Low specific gravity, the lowest specific gravity in engineering plastics.

2. Good chemical resistance.

3. Excellent high and low temperature resistance, excellent mechanical properties.

4. High flow, excellent machining performance, superior surface gloss.

5. UL94 halogen-free flame retardant, no bromoantimony, in line with the European Union halogen-free environmental requirements.

6. Good dielectric resistance, suitable for electrical applications.

7. Excellent weather resistance, good long-term performance, can be used in harsh climate for a long time.

Post time: 16-09-22