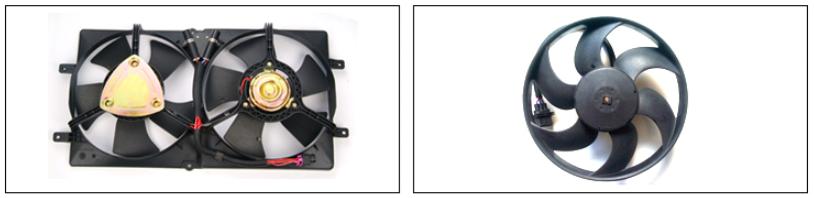

Strength material PP-GF, FR for Fans and industrial products cover

PP Features

The relative density is small, only 0.89-0.91, which is one of the lightest varieties in plastics.

Good mechanical properties, in addition to impact resistance, other mechanical properties are better than polyethylene, molding processing performance is good.

It has high heat resistance and the continuous use temperature can reach 110-120 °C.

Good chemical properties, almost no water absorption, and does not react with most chemicals.

The texture is pure, non-toxic.

Electrical insulation is good.

PP Main Application Field

|

Field |

Application Cases |

|

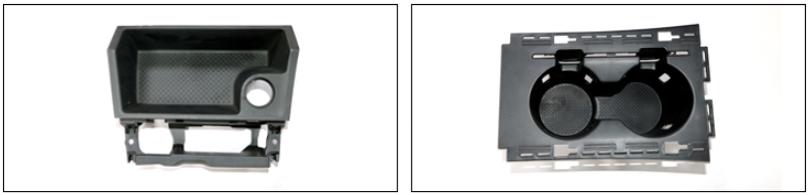

Auto Parts |

Bumper fender (wheel cover), instrument panel, door inner panel , cooling fan, air filter housing,ect. |

|

Home Appliance parts |

Washing machine inner tube, microwave oven sealing strip, rice cooker shell, base of refrigerator, TV housing, etc. |

|

Industrial parts |

Fans, Power tools cover |

SIKO PP Grades And Description

|

SIKO Grade No. |

Filler(%) |

FR(UL-94) |

Description |

|

SP60-GM10/20/30 |

10/20/30% |

HB |

10-40% Glass fiber and Mineral Filler reinforced, high rigidity |

|

SP60-G10/20/30/40 |

10/20/30% |

HB |

10%/20%/30% Glassfiber reinforced, high strength. |

|

SP60F |

None |

V0 |

FR V0@1.6mm, halogen free |

|

SP60F-G20/G30 |

20%-30% |

V0 |

FR V0@1.6mm, 20-30%GF |